EUROPE

2021 | BIOMASS SILO IN FRANCE

Silo designed to adapt it to the special characteristics of the grape seed, a by-product of the wine industry to be used as biomass.

The project includes:

• Silo model 03.82/05, with a 60º inclination cone to facilitate unloading and round head bolts.

• Pneumatic loading system, and therefore the seams between the ferrule plates are specially sealed.

• Sleeve filter located on the catwalk supported by the silo, so that the sleeves can be easily changed.

• Maximum level sensors on the roof and minimum level sensors on the cone for content control.

• Catwalk allows access to the temperature probe and maximum level sensor through a hatch.

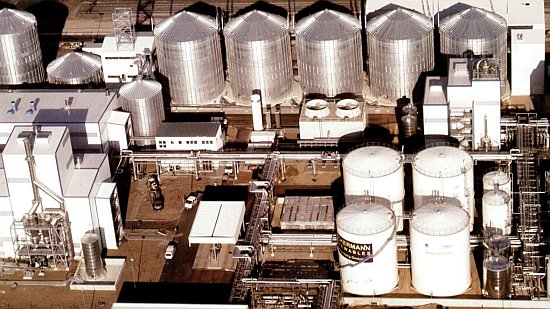

2018 | GRAIN TERMINAL IN ANTWERP, BELGIUM

Grain terminal conceived for the storage of malt and barley. The total capacity of the plant exceeds 20.000 t.

The project includes:

• 37 hopper silos model 07.64/16 45º.

• New reinforced silo design for high grain transfer and flow rates, up to 400 t/h.

• Accessories to preserve the quality of grain: ventilation, temperature control system, level sensors, etc.

• Structures that are fully adapted to the project needs: stair tower, wide catwalks, and different types of supports.

• Turn-key project entirely made by Silos Cordoba.

2016 | STORAGE PLANT IN RUSSIA

Plant conceived for the storage of maize and wheat to supply a feed mill located in Tambov Region, Russia. The total capacity of the plant is 111.924 m³ for the storage of 80.000 t of cereals.

Year 2016.

The project includes:

• 6 silos model 32.08/16 of 17.237 m³ capacity each.

• 4 silos model 9.17/12 45º of 1063 m³ capacity each.

• 10 silos model 6.88/08 60º of 425 m³ capacity each.

• Raw material reception by train and truck.

• Load is done at 200 t/h.

• Unload is done at 120 t/h.

• Pre-cleaners.

• Dryers.

• Filtration systems.

2015 | PROJECT OF HOPPER SILO IN PORTUGAL

Hopper silo conceived for the storage of rice in Figueira Da Foz, Portugal.

The project includes:

• 1 hopper silo model 6.11/8 of 314 m³ capacity.

• The total capacity of the silo is 314 m³ for the storage of 235 t of cereal.

2007 | STORAGE PLANT FOR RAPE AND CEREAL IN FRANKFURT, GERMANY

Storage plant for rape and cereal.

The project includes:

• 3 silos mod. 15.28/7 with a total capacity of 15.650 m³.

• 5 silos mod. 17.57/17 with a total capacity of 75.545 m³.

2006 | STORAGE PLANT IN PORTUGAL

Project for a compound feed manufacturing plant (5 t/h). The total capacity of the plant is 1.200 m³.

The project includes:

• 3 silos model 6.11/8 60º of 327 m³ capacity each.

• 1 silo model 3.82/9 of 122 m³ capacity.

• 2 silos model 2.75/2 60º of 20,85 m³ capacity each.

• It includes also conveying machinery, mixer, scale, and electric equipment.

2020 | WOOD PELLET STORAGE FACILITY IN FRANCE

Facility for the storage and handling of pellets including silos, catwalks, and towers.

The project includes the following structures:

• Elevator tower 5×5.5 h = 32.5m. Open structure, including a zig-zag inclined ladder.

• Elevator tower 0x3.0 h = 26.5m. Open structure, without a ladder.

• Dispatch structure 5m long x 5.0m wide and a maximum height of 12.5m. Partially open structure for truck loading/unloading. The structure has a level on which a reversible conveyor is supported, and an upper level where a silo model S458/4 is supported. It features an inclined ladder to access the maintenance level. The enclosure is based on a substructure made of cold-formed, galvanized sheet S2201GD frames into which a trapezoidal sheet is screwed.

• Silo support tower 35×3.50 h = 21.5m. A catwalk rests on this structure.

• Support towers made of S350GD cold-formed galvanized frames.

• Catwalks made of S350GD galvanised frames. They include collective protection systems such as railings and a floor made of cold-formed galvanized sheet metal as well.

All the structures are bolted by 8.8 hot-dip galvanized screws and are made of S275 JR steel tubular hot-rolled frames with a hot-dip galvanized surface treatment. Additionally, all the passable levels are equipped with skirting boards and galvanized tramex steel grating floor.

2017 | WHEAT STORAGE PLANT IN ITALY

First phase of plant conceived for the reception, storage and expedition of wheat. The total capacity of the plant is 51.710 m³ for the storage of 38.800 t of cereals.

The project includes:

• 6 silos model 20.63/20 of 6.811 m³ capacity each.

• 1 hopper silo model 9.17/19 45º of 1.589 m³ capacity each.

• 3 hopper silos model 4.58/3 60º of 85 m³ capacity each.

• Handling equipment at 200 TPH designed for ATEX21 and ATEX22.

• Catwalks and support structures.

• Aspiration system.

• Cleaning system made up by drum sieve and sieve cleaning.

2015 | STORAGE PLANT FOR WHEAT IN SWEDEN

Silos for the storage of wheat. The silo plant has a capacity of 10,000 t.

The project includes:

• 3 silos model 18.33 with a capacity of 4,100 m³ each.

• The total capacity of the silo plant is 12.300 m³ for the storage of 9.200 t of wheat.

• The assembly of the silos has been performed by our own assembly team.

The silos were sold through the Swedish engineering company Silokonsult, for the company Berte Qvarn, a flour mill located in Slöinge, Sweden.

2012 | GRAIN STORAGE FACILITY IN TURKEY

Silos for the storage of wheat and canola.

The project includes:

• 19 silos mod. 18.33/22 of 7.110 m³ capacity each.

• 27 truck loading silos mod. 4.65/6 of 147 m³ capacity each and 4 45º conic silos mod. 9.17/12 of 1.063 m³ capacity each.

• 6 silos mod. 21.39/22 of 9,752 m³ capacity each.

• 11 silos mod. 14.51/22 of 4.395 m³ capacity each.

• 4 45º conic silos mod. 9.17/12 of 1.063 m³ capacity each.

• The project has a total capacity of 250.168 m³ for the storage of 200.000 t.

The conveying machinery has been delivered by Silos Cordoba.

2007 | PLANT FOR THE RECEPTION OF SHIPS IN AZERBAIJAN

Plant for the reception of ships with two slip extractors, with a total capacity of 300 t, transfer belt to silos, and filling up system.

The project includes:

• Manufacture and assembly of 5 flat silos mod. 16.81/14 with a total capacity of 20.000 m³, continuous flow scale at the entry and the expedition from silos to railroad and trucks.

• Ventilation and temperature monitoring systems and clearing machines. Regarding conveying systems, Silos Córdoba provides two belt conveyors, two bucket elevators and five chain conveyors.