ASIA

2019 | PADDY RICE STORAGE FACILITY IN SRI LANKA

Plant conceived for the storage of paddy rice. The total capacity of the plant is 5.400 m³ for the storage of 4.000 t of cereal.

The project includes:

• 5 hopper silos model 10.70/08 45º of 1.073 m³ capacity each.

• Belt conveyors for loading and unloading.

• Insulation system.

• Aeration system: Centrifugal fans and grain cooler.

• Automatic temperature monitoring system.

The complete project integration has been designed and supplied by Silos Cordoba.

2019 | WHEAT AND BARLEY IN KAZAKHSTAN

Hopper silo for the storage of various types of crops, as well as compound feeds in Kostanay Region, Kazakhstan.

The project includes:

• Hopper silo model 07.64/08 with a capacity of 512m³ (384 tonnes).

• 50 t/h chain conveyor and bucket elevators for loading and unloading.

2017 | WHEAT STORAGE PROJECT IN KAZAKHSTAN

This plant is conceived for the reception, storage and expedition of wheat. The total capacity of the plant is 54.300 m³ for the storage of 40.750 t of cereals.

The project includes:

• 8 silos model 22.92/12 of 6.500 m³ capacity each.

• 4 silos model 6.88/6 60º of 352 m³ capacity each.

• 2 silos model 6.11/9 60º of 360 m³ capacity each.

• 2 train load silos model 4.65/3 60º of 88 m³ capacity each.

• Buffer silo.

• Reception, loading and unloading is done at 100 t/h. All handling equipment is from Silos Córdoba

• 2 hoppers for truck reception and 1 hopper for train reception.

• 2 pre-cleaning lines, 2 cleaning lines and 2 drying lines.

• Base tower 9.5x16m and 31 meters high that houses the cleaning machinery and 10 elevators.

• 2 semi-automatic lines for filling and bagging.

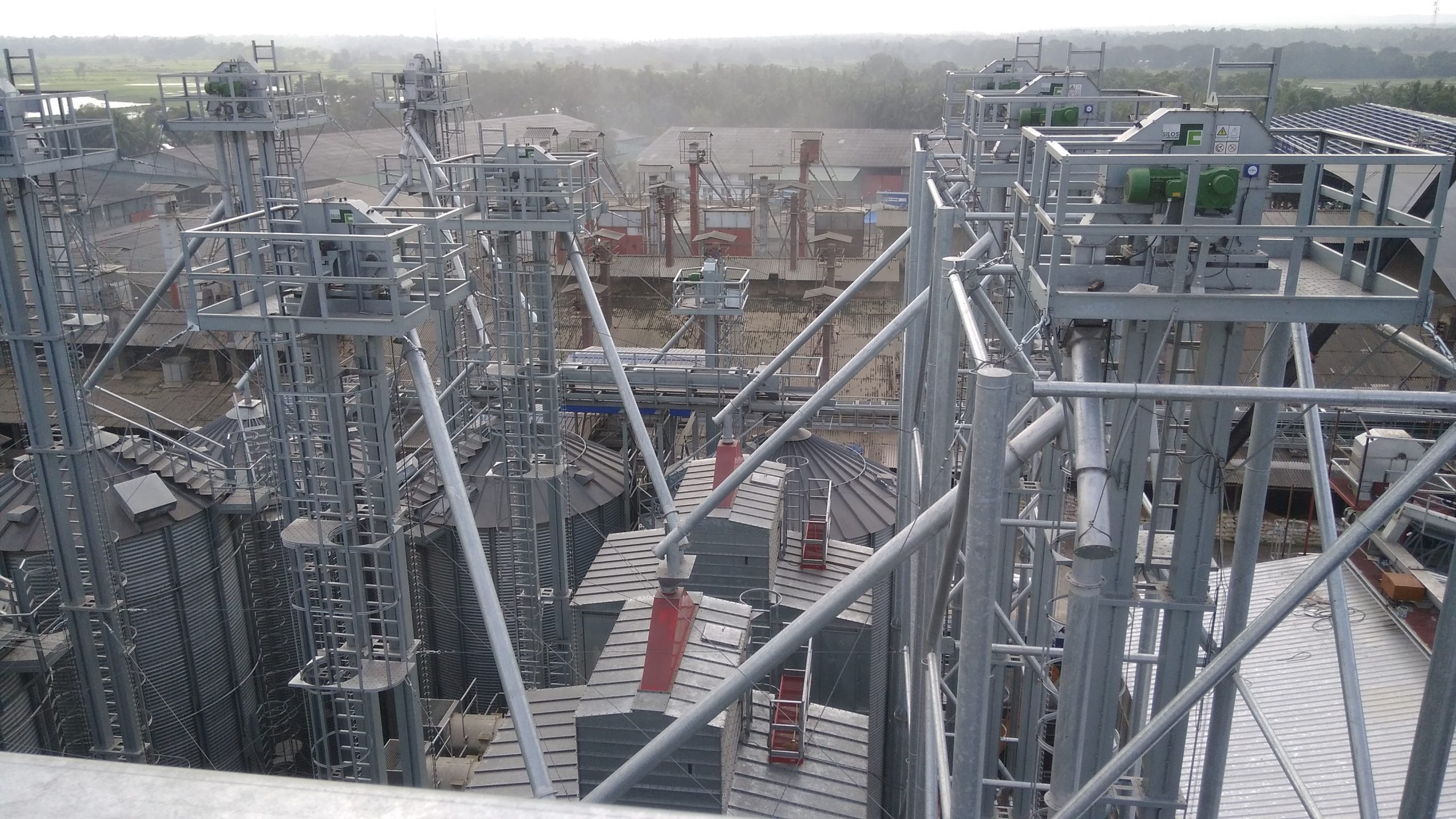

2016 | MAIZE STORAGE PLANT IN MYANMAR

Plant conceived for the storage of maize. The total capacity of the plant is 17.674 m³ for the storage of 13.250 t of maize.

The project includes:

• 4 silos model 16.81/15 of 4.167 m³ capacity each.

• 2 hopper silos model 5.35/9 45º of 262 m³ capacity each.

• 1 hopper silos model 6.11/13 45º de 515 m³ of capacity.

• Drying and cleaning systems.

• Catwalks and towers.

• Handling equipment: Bucket elevators, belt conveyors and chain conveyors.

• Electrical panel.

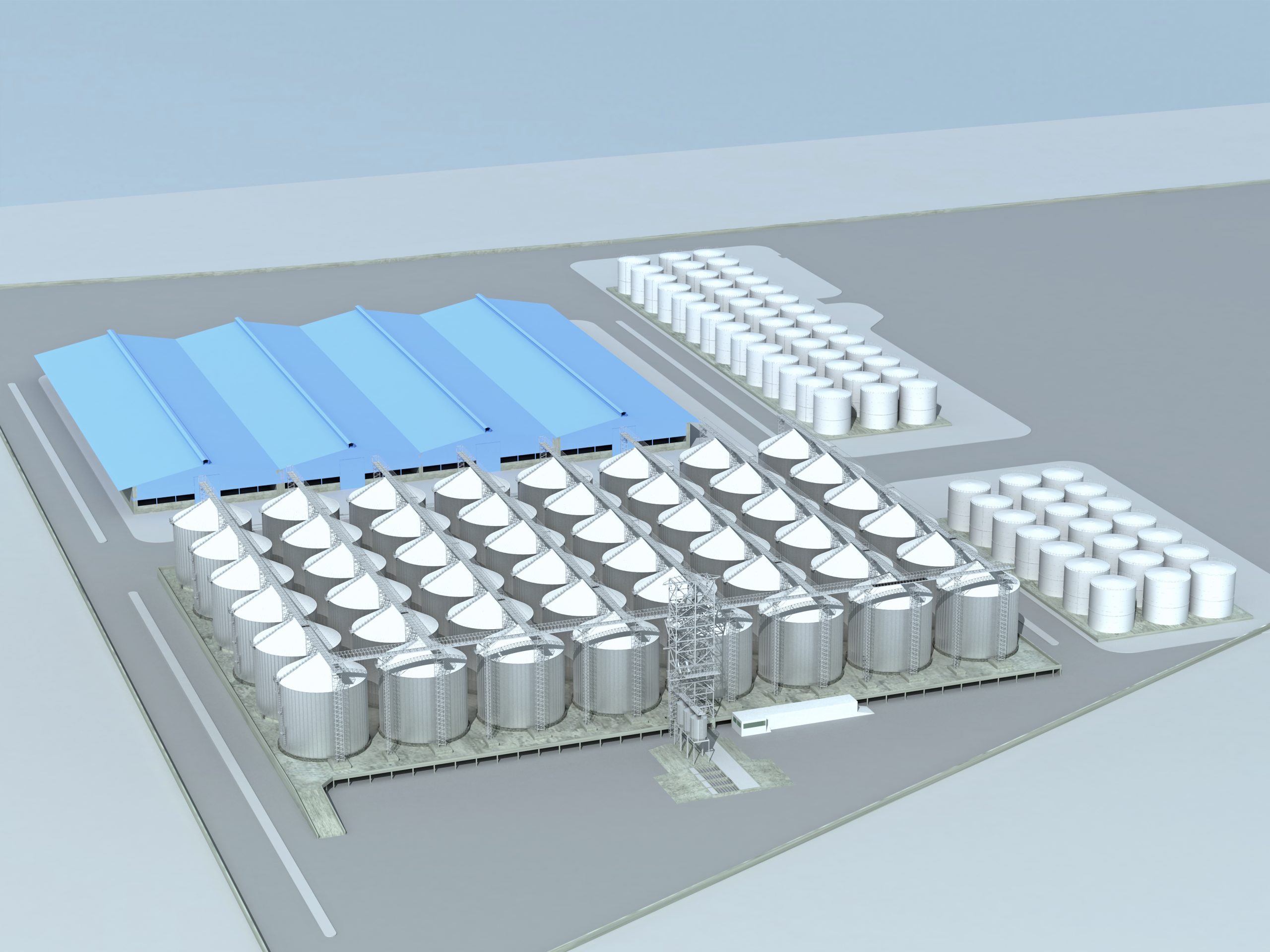

2015 | GRAIN STORAGE FACILITY IN IMAN KHOMEINI PORT, IRAN

Plant conceived for the storage of soya bean, corn and wheat located in Iman Khomeini Port, Iran.

The total capacity of the plant is 489.792 m³ for the storage of 367.000 t of cereal.

The project includes:

• 48 silos model 24.45/17 of 10.204 m³ capacity each.

• Intake conveying capacity: 1.200 t/h (600 t/h double).

• Discharge capacity: 800 t/h (400 t/h double).

2014 | SILOS FACILITY FOR A BREWERY IN MYANMAR

Silos facility of the new Carlsberg brewery in Myanmar for the storage of rice and malt.

The project includes:

• 1 hopper silo model 4.58/10 of 208 m³ capacity.

• The total capacity of the plant is 1.954 m³ for the storage of 1.500 t of cereals.

• 2 hopper silo model 7.64/15 of 873 m³ capacity each.

• In addition, the silos are equipped with ventilation and a thermometry system for maintaining stored grain quality.

2013 | GRAIN STORAGE FACILITY IN KAZAKHSTAN

Storage plant for wheat.

The project includes:

• 4 silos model 17.57/13 of 4.003 m³ capacity each.

• 3 truck loading silos model 3.50/6 cone 60º of 74,07 m³ capacity each.

• 3 hopper silos model 5.35/09 45º of 262 m³ capacity each.

• The total capacity of the facility is 17.020 m³ for the storage of 12.800 t of cereals.

The conveying machinery has been delivered by Silos Cordoba. Loading and unloading is done at 100 t/h.

2012 | GRAIN STORAGE FACILITY IN TURKEY

Silos for the storage of wheat and canola.

The project includes:

• 19 silos mod. 18.33/22 of 7.110 m³ capacity each.

• 27 truck loading silos mod. 4.65/6 of 147 m³ capacity each and 4 45º conic silos mod. 9.17/12 of 1.063 m³ capacity each.

• 6 silos mod. 21.39/22 of 9,752 m³ capacity each.

• 11 silos mod. 14.51/22 of 4.395 m³ capacity each.

• 4 45º conic silos mod. 9.17/12 of 1.063 m³ capacity each.

• The project has a total capacity of 250.168 m³ for the storage of 200.000 t.

The conveying machinery has been delivered by Silos Cordoba.

2009 | WHEAT STORAGE PLANT IN VIETNAM

Storage plant for Wheat.

The project includes:

• The installation is composed by 4 silos mod. 13.75/14 with a total capacity of 10.264 m³.

• Filling up is done at 100 t and unloading is done at 50 t/h.

• Total capacity of 10.264 m³.

The conveying machinery has been delivered by Silos Cordoba.

2019 | HANDLING EQUIPMENT IN KAZAKHSTAN

Handling equipment in a wheat and barley storage plant in the North of Kazakhstan.

The project includes:

• Handling equipment for loading and unloading: 100 t/h chain conveyors, bucket elevators.

• Connection with the existing receiving pit and grain dryer.

2017 | GRAIN STORAGE FACILITY IN OSKEMEN, KAZAKHSTAN

Storage facility for wheat, barley, buckwheat, oats and sunflower in Oskemen, Kazakhstan.

“Vertex-Vostok” is engaged in processing a wide variety of cereal crops and is a producer of a variety of cereals, especially buckwheat.

Production is carried out at a plant equipped with European machinery. Due to the growing demand for products, the management decided to expand the production capacity. Moreover, to ensure the raw material needs of the plant, it was required to install a complex for storing and transporting cereals.

The project includes:

• Flat bottom silo 14.51/11 with 2.313 m³.

• 3 flat bottom silo 5.35/13 with 345 m³.

• Receiving and handling equipment 40 t/h.

• Elevator tower 3х3 with height 30 meters.

2016 | PADDY RICE STORAGE PLANT IN SRI LANKA

Plant conceived for the storage of rice. The total capacity of the plant is 118.966 m³ for the storage of 89.500 t of rice.

The project includes:

• 20 silos model 19.10/16 of 5.771 m³ capacity each.

• 3 hopper silos model 7.64/11 45º of 667 m³ capacity each.

• 3 hopper silos model 6.11/14 45º of 515 m³ capacity each.

• Bucket elevators and belt conveyors.

• Silos equipped with level detectors, ventilation system and thermometry.

• Catwalks and towers.

• Drying and cleaning systems.

• Electrical panel.

2016 | PADDY RICE STORAGE PLANT IN THAILAND

Storage plant for paddy rice with a total storage capacity of 21.500 m³ in the Ubon Ratchathani Province, Thailand. With a density of 0,56 t/m³ and a compaction factor of 5%, the total capacity in tons is 12.630.

The project includes:

• The storage plant has 12 hopper silos model 10,70/15 with 45º cone with an unit capacity of 1.052,52 t of paddy rice. Matrix silo distribution of 3×4.

• Maximum and minimum sensors.

• Automatic Temperature Monitoring System

• Aeration system made up by:

– Aeration pipes and connections

– Centrifugal fan

– Exhaust fan on the roof

Besides, the storage plant includes all necessary catwalks and supports for the loading handling equipment.

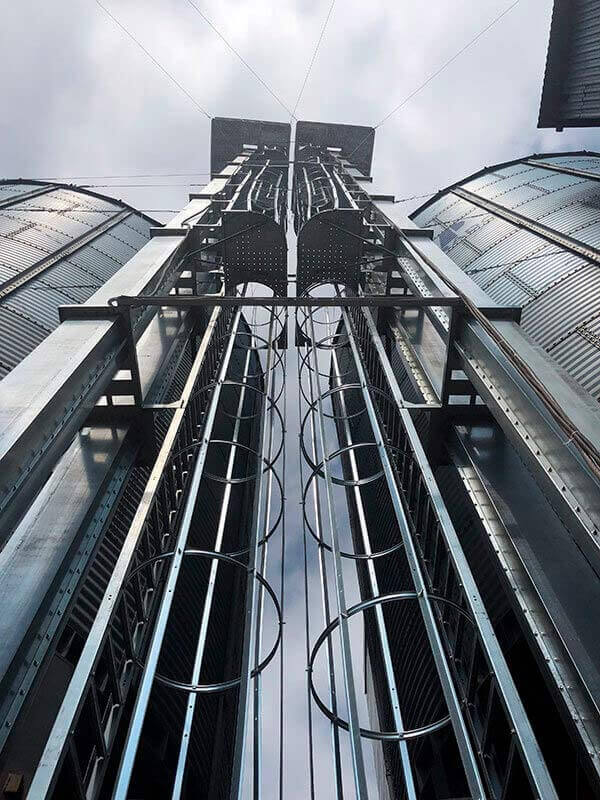

2016 | GRAIN TERMINAL AKTAU PORT, KAZAKHSTAN

Erection and commissioning of Grain Terminal in Aktau port, Kazakhstan, with a total storage capacity of 60.000 tons.

It’s the first phase of a turnkey project, that currently has 6 flat bottom silos with a capacity of 10.000 tons of wheat each.

The whole Grain Terminal has been designed with the objective to handle a target capacity of one million tons per year, and is equipped with all necessary safety and anti-wear systems.

The project includes:

• Complete aspiration system for dust and fine particles installed on reception intake, cleaning system, elevators and loading conveyors. Due to the features of the Grain Terminal, these impurities are transferred back to the grain flow during the ship loading process.

• Two independent weighing systems: one for the grain reception (after cleaning), another for expedition (before loading vessels).

• Silo unloading system with belt conveyors. Capacity of 500 t/h.

• Impurities disposal system able to collect all the impurities from the cleaning system and transfer them to a truck load silo.

• Silos are designed according to the seismic zone, wind speed and snow load in the area. Also, they are equipped with:

√ Aeration system made by centrifugal fans, aeration grill with H type and exhaust fans.

√ Complete unloading silo system with central and lateral discharge hoppers, motorized and manual slide gates. To minimize operation failure, each silo outlet has a flow regulator able not only to supply 500 t/h capacity but also the ability to prevent blockage in the unloading conveyors.

√ Automatic control temperature system, which is integrated with the electrical panel, which enables automatic aeration.

√ Silos are designed to be fumigation compatible. This means all silo joints are sealed.

Roof vent locks are also installed to be used when the fumigation process occurs.

• 2 Elevator tower supports with step ladder to improve the maintenance. They have several maintenance platforms not only for the elevators but also for the weighing system inside, that is why both towers are covered, to protect the weighing system from the wind.

• Ship loader with a capacity of 500 t/h. Ship loader mounted on rails.

• Silo unloading system with belt conveyors. Capacity of 500 t/h.

• Silo loading system with chain conveyors. Capacity of 500 t/h.

• Two cleaning lines combining magnet separator and drum sieves.

• Two independent train reception lines: pit intakes fully designed and manufactured by Silos Córdoba.

• Catwalks, tower supports for catwalks.

• Fire extinguishing

• Electrical panel as well as cables and cable tray for the complete installation. This equipment allows for the full automatization of the grain terminal, that can be operated by only 6 people.

The installation of the project has been done by Silos Córdoba Kazakhstan.

2013 | MAIZE STORAGE PROJECT IN SRI LANKA

Grain storage facility for the storage of maize.

The project includes:

• 2 galvanized steel silos model 22.92/13 of 7.025 m³ capacity each.

• 1 hopper silo for truck loading 3.50/5 45º.

• Loading and unloading is done at 80 t/h.

• 2 hopper silos model 6.88/13 45º of 618 m³ capacity each.

• The total capacity of the plant is 15.354 m³ for the storage of 11.515 t of cereal.

The conveying machinery has been delivered by Silos Cordoba.

2012-2016 | EXPANSION OF STORAGE PLANT IN KAZAKHSTAN

Plant conceived for the storage of wheat, barley, rapeseed, flax and sunflower. The total capacity of the plant is 43.882 m³ for the storage of 33.000 t of cereals.

The project includes:

• 4 silos model 17.57/13 of 4.003 m³ capacity each.

• 4 silos model 22.92/13 of 6.573 m³ capacity each.

• 6 hopper silos model 5.35/9 (45º) of 263 m³ capacity each.

• 4 hopper silos model 7.64/10 (60º) of 659 m³ capacity each.

• 2 hopper silos model 1.85/2 (60º) for automatic weighing packer.

• Loading and unloading is done at 100 t/h.

• The conveying machinery – chain conveyors, belt conveyor, screw conveyors, bucket elevators – has been delivered by Silos Córdoba.

• Cereal sampling probe (DV company, made in Italy) supplied by Silos Córdoba.

• Grain analyzer Foss (Denmark).

• 2 units receiving pit for truck.

• Cleaning system consist of: rotatory drum cleaner (scalperator) Jubus 100 t/h, grain cleaner Jubus mod. L-JS-16, aspiration and cyclone.

• 2 units vertical grain dryer machine Cedar model SCM 6-12, 40 t/h,

• 2 bulk expeditions for train and also a third option for train expedition: 2 lines of packing grain in sacks including industrial automatic weighing packer mod. Ilerfil ANG, and sewing machine Ilersew MPR with Fischbein 100.

• Electrical panel

• Elevator tower 8×8, h=30 m.

Engineering and supply of equipment to connect existing flour mill and two outdoor warehouses.

2007 | PLANT FOR THE RECEPTION OF SHIPS IN AZERBAIJAN

Plant for the reception of ships with two slip extractors, with total capacity of 300 t, transfer belt to silos and filling up system.

The project includes:

• Manufacture and assembly of 5 flat silos mod. 16.81/14 with a total capacity of 20.000 m³, continuous flow scale at the entry and at the expedition from silos to railroad and trucks.

• Ventilation and temperature monitoring systems and clearing machines.

Regarding conveying systems, Silos Córdoba provides two belt conveyors, two bucket elevators and five chain conveyors.

2006 | STORAGE FACILITY FOR RICE IN THAILAND

Two storage plants for rice.

The project includes:

• The first installation includes 12 square silos of 5,5×5,5 meters with a total storage capacity of 3.636 m³.

• The second installation includes six square silos of 5,5×5,5 meters with a total capacity of 1.800 m³.