HEAVY DUTY RANGE

KEY FEATURES

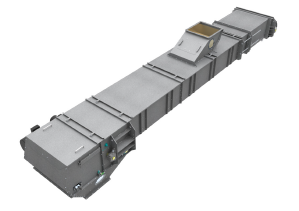

Silos Córdoba introduces the TBC Enclosed Belt Conveyor, engineered for continuous, year-round operation. Constructed from hot-dip galvanized welded plate, this conveyor efficiently handles a diverse range of grains, seeds, legumes, and pellets.

Designed for 24/7 operation, it effortlessly transports large quantities of cereal while offering simplified maintenance.

Notable advantages of the enclosed belt conveyor design include its ability to prevent grain contamination, its fully enclosed belt without exposed metal parts or bearings within the conveying section, and its reduced power consumption compared to traditional chain conveyors, resulting in lower noise levels and minimized grain damage.

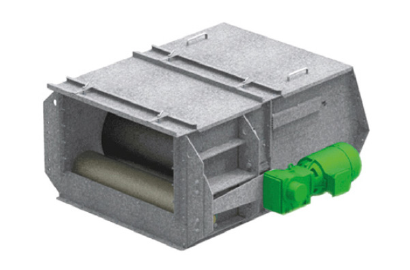

HEAD SECTIONS

The head section of the enclosed belt conveyor features direct shaft coupling.

Access points are strategically positioned for easy part removal, facilitating swift maintenance.

Equipped with inspection hatches, a jam detector, and a bearing regulation system, the head section ensures smooth operation. Additionally, it incorporates a drum cleaning system with automatic control and is protected by HARDOX 450 for extended service life.

A reaction arm, designed and manufactured by Silos Córdoba, absorbs the torque generated by the gear motor.

TENSIONING SECTION

This section comprises an automatic grain recovery system, easily accessible registration gates, and a detachable rear for pulley maintenance.

Butyl-sealed joints are employed to prevent dust leakage and contamination of grains by external agents or moisture.

Utilizing the bearing regulation system, it becomes feasible to align and rectify any pulley deviations or misalignments, thereby ensuring optimal conveyor performance.

The housing bearings are reinforced with welded reinforcements that have been hot-dip galvanized.

INTERMEDIATE SECTION

Featuring a simple bolt-based design, the intermediate section incorporates a self-centering system for rollers, correcting belt deviation.

Key advantages include the use of anti-wear HDPE 1000 material for the base, ensuring smooth belt operation and minimizing wear on the conveyor bottom. Maintenance tasks are simplified with easily removable tap covers.

INPUT AND OUTPUT HOPPERS

Protected by highly resistant HARDOX 450 material, input and output hoppers feature inspection windows for enhanced monitoring.

Equipped with register dampers, these hoppers support variable height support installation in intermediate sections as per installation requirements.

A notable advancement of the new design is the inclusion of large inspection windows for internal monitoring, along with facilitated access through the registration gate.